Product Parameters

Operate Instruction

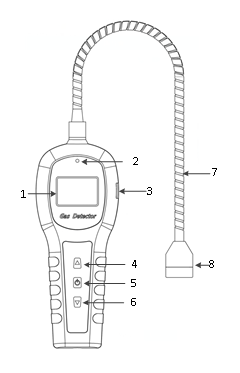

Detector Instruction The specification of instrument parts is shown in Figure 2 and table 2.3.2 Power on Key description is shown in table 3 Table 3 Key Function| Button | Function description | Note |

| ▲ | Up, value +, and screen indicating function | |

| Long press 3s to boot up Press to enter the menu Short press to confirm operation Long press 8s to restart the instrument | |

| ▼ | Scroll down, left and right switch flicker, screen indicating function |

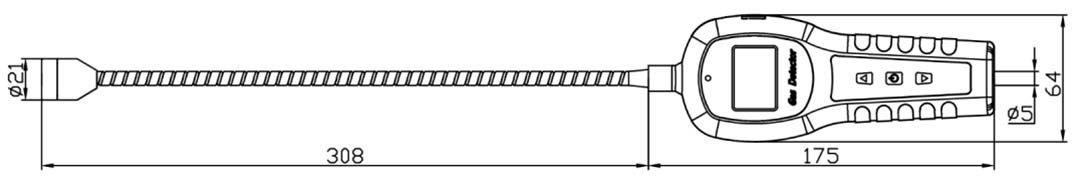

3s to start up ● Plug in the charger and the instrument will start automatically. There are two different ranges of the instrument. The following is an example of a range of 0-100% LEL.● Sensor Type: Catalytic sensor ● Detect gas: CH4/Natural gas/H2/ethyl alcohol ● Measure range: 0-100%lel or 0-10000ppm ● Alarm point: 25%lel or 2000ppm ,adjustable ● Accuracy: ≤5%F.S ● Alarm: Voice + vibration ● Language: Support English& Chinese menu switch ● Display: LCD digital display, Shell Material: ABS ● Working voltage: 3.7V ● Battery capacity: 2500mAh Lithium battery ● Charging voltage: DC5V ● Charging time: 3-5hours ● Ambient environment: -10~50℃,10~95%RH ● Product Size: 175*64mm( not including the probe) ● Weight: 235g ● Packing: Aluminum case The dimension diagram is shown in Figure 1:

3s to start up ● Plug in the charger and the instrument will start automatically. There are two different ranges of the instrument. The following is an example of a range of 0-100% LEL.● Sensor Type: Catalytic sensor ● Detect gas: CH4/Natural gas/H2/ethyl alcohol ● Measure range: 0-100%lel or 0-10000ppm ● Alarm point: 25%lel or 2000ppm ,adjustable ● Accuracy: ≤5%F.S ● Alarm: Voice + vibration ● Language: Support English& Chinese menu switch ● Display: LCD digital display, Shell Material: ABS ● Working voltage: 3.7V ● Battery capacity: 2500mAh Lithium battery ● Charging voltage: DC5V ● Charging time: 3-5hours ● Ambient environment: -10~50℃,10~95%RH ● Product Size: 175*64mm( not including the probe) ● Weight: 235g ● Packing: Aluminum case The dimension diagram is shown in Figure 1:Equipment maintenance

4.1Notes 1)When charging, please keep the instrument shutdown to save charging time. In addition, if switch on and charging, the sensor might be affected by the difference of charger (or the difference of charging environment), and in serious cases, the value might be inaccurate or even alarm. 2)It needs 3-5 hours for charging when the detector is auto-power off. 3)After get full charged, for combustible gas, it can work 12hours continuously (Except for alarm) 4)Avoid using the detector in a corrosive environment. 5)Avoid contacting with water. 6)Charge the battery every one to two-three months to protect its normal life if it is not used for a long time. 7)Please be sure to start the machine in normal environment. After starting, take it to the place where the gas is to be detected after the initialization completed. 4.2Common Problems and Solutions Common Problems and Solutions as table 4. Table 4 Common Problems and Solutions| Failure phenomenon | Cause of the malfunction | Treatment |

| Unbootable | low battery | Please charge in time |

| System halted | Press the button for 8s and restart the device button for 8s and restart the device | |

| Circuit fault | Please contact your dealer or manufacturer for repair | |

| No response on the detection of gas | Circuit fault | Please contact your dealer or manufacturer for repair |

| Display inaccuracy | Sensors expired | Please contact your dealer or manufacturer for repair to change the sensor |

| Longtime no calibration | Please calibrate timely | |

| Calibration failure | Excessive sensor drift | Calibrate or replace the sensor in time |

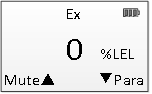

Figure 3 Main Interface

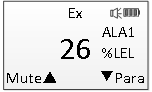

The instrument testing near the location of the need to detect, the instrument will show detected density, when the density exceeds bid, instrument will sound alarm, and accompanied by vibration, the screen above the alarm icon appears, as shown in figure 4, the lights changed from green to orange or red, orange for first alarm, red for the secondary alarm.

appears, as shown in figure 4, the lights changed from green to orange or red, orange for first alarm, red for the secondary alarm.

Figure 4 Main interfaces during alarm

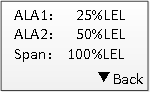

Press ▲ key can eliminate alarm sound, alarm icon change to . When the instrument concentration is lower than the alarm value, the vibration and alarm sound stop and the indicator light turns green. Press ▼ key to display instrument parameters, as shown in figure 5.

. When the instrument concentration is lower than the alarm value, the vibration and alarm sound stop and the indicator light turns green. Press ▼ key to display instrument parameters, as shown in figure 5.

Figure 5 Instrument Parameters

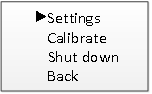

Press ▼ key return to the main interface.3.3 Main Menu Press key on the main interface, and into menu interface, as shown in figure 6.

key on the main interface, and into menu interface, as shown in figure 6.

Figure 6 Main Menu

Setting: sets the alarm value of the instrument, Language. Calibration: zero calibration and gas calibration of the instrument Shutdown: equipment shutdown Back: returns to the main screen Press ▼or▲ to select function, press to perform an operation.3.4 Settings Settings Menu is shown in Figure 8.

to perform an operation.3.4 Settings Settings Menu is shown in Figure 8.

Figure 7 Settings Menu

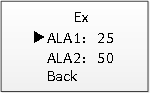

Set Parameter: Alarm Settings Language: Select system language 3.4.1Set Parameter The settings parameter menu is shown in Figure 8. Press ▼ or ▲ to choose the alarm that you want to set, then press to execute operation.

to execute operation.

Figure 8 Alarm level selections

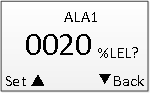

For example, set a level 1 alarm as shown in figure 9, ▼ change the flicker bit, ▲value add 1. The alarm value set must be ≤ the factory value.

Figure 9 Alarm setting

After setting, press to enter the setting interface of alarm value determination, as shown in Figure 10.

to enter the setting interface of alarm value determination, as shown in Figure 10.

Figure 10 Determine the alarm value

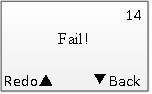

Press , success will be displayed at the bottom of the screen, and failure will be displayed if the alarm value is not within the allowed range.3.4.2 Language Language menu is shown in Figure 11. You can choose Chinese or English. Press ▼ or ▲ to choose language, press

, success will be displayed at the bottom of the screen, and failure will be displayed if the alarm value is not within the allowed range.3.4.2 Language Language menu is shown in Figure 11. You can choose Chinese or English. Press ▼ or ▲ to choose language, press to confirm.

to confirm.

Figure 11 Language

3.5 Equipment calibration When the instrument is used for a period of time, the zero drift appears and the measured value is inaccurate, the instrument needs to be calibrated. Calibration requires standard gas, if there is no standard gas, gas calibration cannot be performed. To enter this menu, need to enter the password as shown in figure 12, which is 1111

Figure 12 Password input interface

After completing the password input, press enter to the device calibration selection interface, as shown in Figure 13: Select the action you want to take and press

enter to the device calibration selection interface, as shown in Figure 13: Select the action you want to take and press  enter.

enter.

Figure 13 Correction type selections

Figure 1 Dimension diagram

Product lists shown as table 1. Table 1 Product list| Item No. | Name |

| 1 | Portable combustible gas leak detector |

| 2 | Instruction manual |

| 3 | Charger |

| 4 | Qualification Card |

Table 2 Specification of instrument parts

| No. | Name |

Figure 2 Specification of instrument parts |

| 1 | Display Screen | |

| 2 | Indicator light | |

| 3 | USB charging port | |

| 4 | Up key | |

| 5 | Power button | |

| 6 | Down Key | |

| 7 | Hose | |

| 8 | Sensor |

Figure 14 Confirm the reset prompt

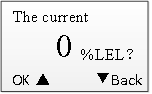

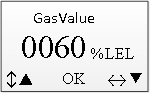

Zero calibration Enter the menu to perform zero calibration in clean air or with 99.99% pure nitrogen. The prompt for determination of zero calibration is shown in Figure 14 .Confirm according to ▲.Success will appear at the bottom of the screen. If the concentration is too high, the zero correction operation will fail. Gas calibration This operation is performed by connecting the standard gas connection flowmeter through a hose to the detected mouth of the instrument. Enter the gas calibration interface as shown in Figure 15, input the standard gas concentration.

Figure 15 Set the standard gas concentration

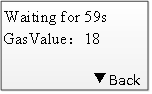

The concentration of the input standard gas must be ≤ the range. Press to enter the calibration waiting interface as shown in Figure 16 and enter the standard gas.

to enter the calibration waiting interface as shown in Figure 16 and enter the standard gas.

Figure 16 Calibration waiting interface

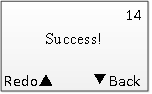

Automatic calibration will be executed after 1 minute, and the successful calibration display interface is shown in Figure 17.

Figure 17 Calibration success

If the current concentration is too different from the standard gas concentration, calibration failure will be shown, as shown in Figure 18.

Figure 18 Calibration failure