Technical parameter

Technical parameters of gas-detecting

Table 1: Technical parameters of gas-detecting| Measured Gas | Gas Name | Technical standards | ||

| Measuring Range | Resolution | Alarming point | ||

| CO2 | Carbon dioxide | 0-50000ppm | 70ppm | 2000ppm |

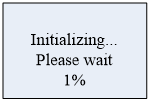

Figure 5: Boot display interface

The function of device initialization is that when the parameter of device is stable, it will preheat the sensor of instrument. X% is currently running time, the running time will vary according to the type of sensors. As what shows in Figure 6:

Figure 6: Display interface

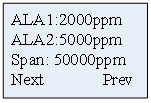

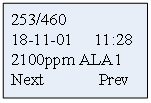

7.3 Check parameters If there is a need to see the gas parameters and recording data, you could anyone of the four arrow buttons to enter the parameter-checking interface on the concentration display interface. For example, press to see the interface below. As shows in Figure 7:

to see the interface below. As shows in Figure 7:

Figure 7: Gas parameters

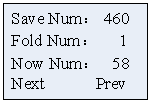

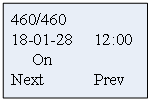

Press to enter the memory interface (Figure 8), press

to enter the memory interface (Figure 8), press  to enter specific alarming recording interface (Figure 9), press

to enter specific alarming recording interface (Figure 9), press  back to detecting display interface.

back to detecting display interface.

Figure 8: memory state

Save Num: The total number of records for the storage. Fold Num: When the written record is full, it will start from the first cover storage, and coverage counts will add 1. Now Num: The index of Currently storage Press or

or  to the next page, alarming records are in the Figure 9Display from the last records.

to the next page, alarming records are in the Figure 9Display from the last records.

Figure 9: boot record

Figure 10: alarm record

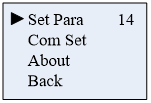

7.4 Menu operation When in the real-time concentration display interface, press to enter the menu. The menu interface are shown in Figure 11, press

to enter the menu. The menu interface are shown in Figure 11, press or

or  to choose any function interface, press

to choose any function interface, press  to enter this function interface.

to enter this function interface.

Figure 11: Main menu

Press or

or  to the next page, press

to the next page, press  back to the detecting display interface. Notes: when checking parameters, not pressing any keys for 15s, the instrument will automatically return to the detection and display interface.Function description: Set Para: Time settings, alarm value settings, device calibration and switch mode. Com Set: Communication parameters settings. About: The version of device. Back: Back to the gas-detecting interface. The number on the upper right is the countdown time, when there is no key operation 15 seconds later, will exit the menu.

back to the detecting display interface. Notes: when checking parameters, not pressing any keys for 15s, the instrument will automatically return to the detection and display interface.Function description: Set Para: Time settings, alarm value settings, device calibration and switch mode. Com Set: Communication parameters settings. About: The version of device. Back: Back to the gas-detecting interface. The number on the upper right is the countdown time, when there is no key operation 15 seconds later, will exit the menu.

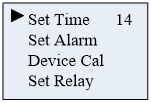

Figure 12: System setting menu

Function description: Set Time: Time settings, including year, month, day, hours and minutes Set Alarm: Set alarm value Device Cal: Device calibration, including zero point correction, correction of calibration gas Set Relay: Set relay outputAcronyms

ALA1 Low alarm ALA2 High alarm Prev Previous Set Para Parameter settings Com Set Communication settings Num Number Cal Calibration Addr Address Ver Version Min MinutesProduct configuration

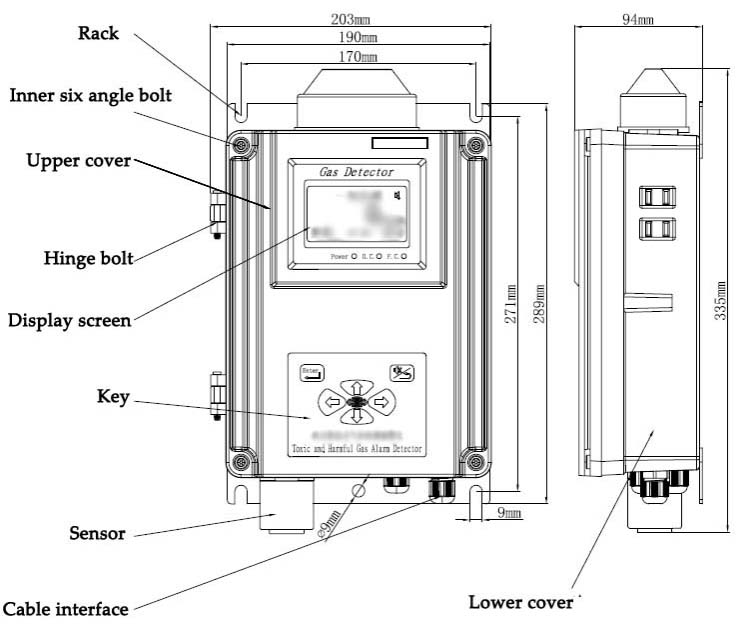

1. Wall-mounted detecting alarm one 2. 4-20mA output module (option) 3. RS485 output (option) 4. Certificate one 5. Manual one 6. Installing component oneConstruction and installing

6.1 device installing Installing dimension of device is shown in Figure 1.Firstly, punch at the proper height of wall, install expanding bolt, then fix it up.

Figure 1: installing dimension

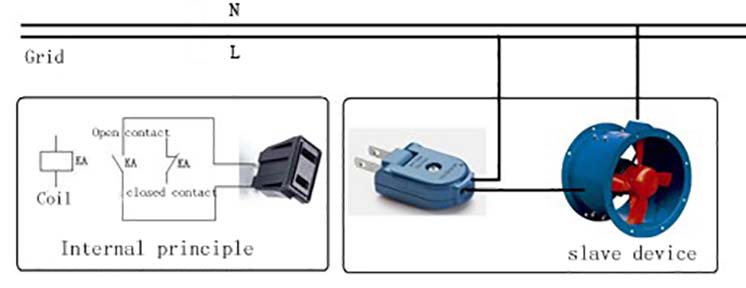

6.2 Output wire of relay When gas concentration exceeds the alarming threshold, the relay in the device will switch on/off, and users could connect linkage device such as fan. The reference picture is shown in Figure 2. Dry contact is used in the inside battery and device need to be connected in the outside, pay attention to the safe use of electricity and be careful of electric shock.

Figure 2: wiring reference picture of relay

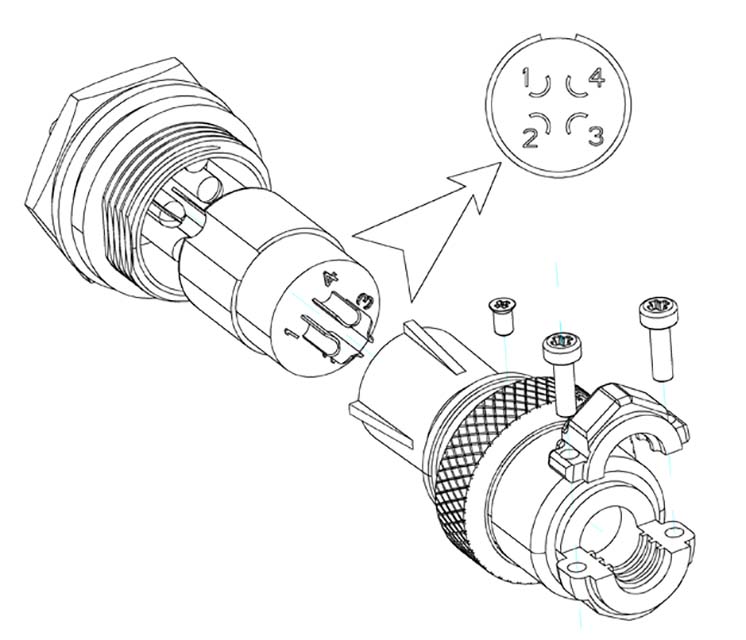

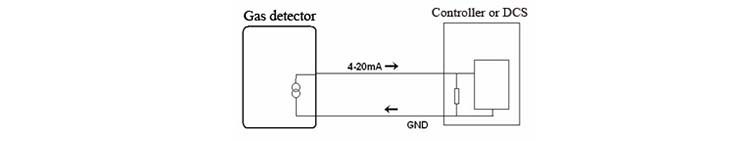

Provides two relay outputs, one is normally open and another is normally closed. Figure 2 is a schematic view of the normally open. 6.3 4-20mA output wiring [option] Wall-mounted gas detector and control cabinet (or DCS) connect via 4-20mA Current signal. The interface shown in Figure 4:

Figure3: Aviation plug

The 4-20mA wiring corresponding shown in Table2: Table 2: 4-20mA wiring corresponding table| Number | Function |

| 1 | 4-20mA signal output |

| 2 | GND |

| 3 | None |

| 4 | None |

Figure 4: 4-20mA connection diagram

The flow path of connecting leads is as follows: 1. Pull the aviation plug off the shell, unscrew the screw, get out the inner core marked "1, 2, 3, 4". 2. Put 2-core shielding cable through the outer skin, then according to Table 2 terminal definition welding wire and conductive terminals. 3. Install the components to the original place, tighten all the screws. 4. Put the plug in the socket, and then tighten it. Notice: As to the processing method of shielding layer of cable, please execute a single end connection, connect shielding layer of controller end with the shell In order to avoid interference. 6.4 RS485 connecting leads [option] The instrument can connect controller or DCS through the RS485 bus. Connection method similar 4-20mA, please refer 4-20mA wiring diagram.Operation instruction

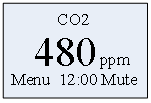

The first line shows the detecting name, the concentration values is shown in the middle, the unit is shown on the right, year ,date and time will be shown circularly. When alarming occurs,

The first line shows the detecting name, the concentration values is shown in the middle, the unit is shown on the right, year ,date and time will be shown circularly. When alarming occurs,  will be shown on the upper right corner, the buzzer will buzz, the alarm will twinkle, and relay respond according to the settings; If you press the mute button, the icon will become

will be shown on the upper right corner, the buzzer will buzz, the alarm will twinkle, and relay respond according to the settings; If you press the mute button, the icon will become , the buzzer will be silent, no alarm icon is not displayed. Every half an hour, it saves the current concentration values. When the state of alarm changes, it records it. For example, it changes from normal to level one, from level one to level two or level two to normal. If it keeps alarming, recording will not be occurred.7.2 Function of buttons Button functions are shown in Table 3. Table 3: Function of buttons

, the buzzer will be silent, no alarm icon is not displayed. Every half an hour, it saves the current concentration values. When the state of alarm changes, it records it. For example, it changes from normal to level one, from level one to level two or level two to normal. If it keeps alarming, recording will not be occurred.7.2 Function of buttons Button functions are shown in Table 3. Table 3: Function of buttons | Button | Function |

| Display the interface timely and Press the button in the menu Enter the child menu Determine the set value |

| Mute Back to the former menu |

| Selection menuChange the parameters |

| Selection menu Change the parameters |

| Select the setting value column Decrease the setting value Change the setting value. |

| Select the setting value column Change the setting value. Increase the setting value |

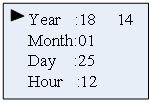

to enter. As Figure 13 shows:

to enter. As Figure 13 shows:

Figure 13: Time setting menu

Icon is referring to the currently selected to adjust the time, press

is referring to the currently selected to adjust the time, press or

or  to change data. After selecting data, press

to change data. After selecting data, press  or

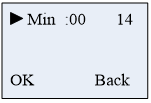

or to choose to regulate other time functions. Function description: ● Year set range 18 ~ 28 ● Month set range 1~12 ● Day set range 1~31 ● Hour set range 00~23 ● Minute set range 00 ~ 59. Press

to choose to regulate other time functions. Function description: ● Year set range 18 ~ 28 ● Month set range 1~12 ● Day set range 1~31 ● Hour set range 00~23 ● Minute set range 00 ~ 59. Press  to determine the setting data, Press

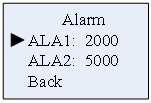

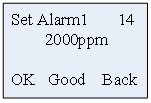

to determine the setting data, Press  to cancel, back to former level.7.4.2 Set Alarm Select "Set Alarm", press

to cancel, back to former level.7.4.2 Set Alarm Select "Set Alarm", press  to enter. The following combustible gas devices to be an example. As shown in figure 14:

to enter. The following combustible gas devices to be an example. As shown in figure 14:

Figure 14: Combustible gas alarm value

Choose Low alarm value is set, and then press to enter the Settings menu.

to enter the Settings menu.

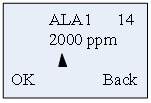

Figure 15: Set the alarm value

As shown in figure 15, press or

or to Switch data bits, press

to Switch data bits, press  or

or to increase or decrease data. After the completion of the set, press

to increase or decrease data. After the completion of the set, press , confirm numerical interface into the alarm value, press

, confirm numerical interface into the alarm value, press  to confirm, after the success of the Settings below 'success', whereas tip 'failure', as shown in figure 16.

to confirm, after the success of the Settings below 'success', whereas tip 'failure', as shown in figure 16.

Figure 16: Settings success interface

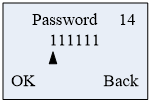

Note: set the alarm value must be smaller than the factory values (oxygen lower limit alarm value must be greater than the factory setting); otherwise, it will be set a failure. After level set is finished, it returns to the alarm value set type selection interface as shown in figure 14, the secondary alarm operation method is same as above.7.4.3 Equipment calibration Note: powered on, initialize the rear end of zero calibration, calibration gas, correction must be corrected when zero air calibration again. Parameter Settings - > calibration equipment, enter the password: 111111

Figure 17: Input password menu

Correct password into the calibration interface.

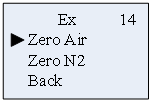

Figure 18: Calibration option

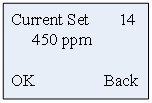

● Zero in Fresh Air (assumed to be 450ppm) In the fresh air, assumed to be 450ppm, choose 'Zero Air' function, then press into the Zero in Fresh Air interface. Determining the current gas 450ppm, press

into the Zero in Fresh Air interface. Determining the current gas 450ppm, press  to confirm, below middle will display 'Good' vice display 'Fail' .As shown in figure 19.

to confirm, below middle will display 'Good' vice display 'Fail' .As shown in figure 19.

Figure 19: Select zero

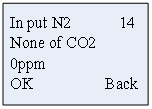

After the completion of the Zero in Fresh Air, press back to return. ● Zero in N2 If gas calibration is needed, this needs to operate under the environment of a standard gas. Pass into the N2 gas, choose 'Zero N2' function, press

back to return. ● Zero in N2 If gas calibration is needed, this needs to operate under the environment of a standard gas. Pass into the N2 gas, choose 'Zero N2' function, press  to enter. As shown in figure 20.

to enter. As shown in figure 20.

Figure 20: Confirmation interface

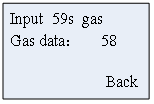

Press , into the calibration gas interface, as shown in figure 21:

, into the calibration gas interface, as shown in figure 21:

Figure 21: Gas calibration

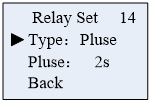

Display the current detecting gas concentration values, pipe in standard gas. As the countdown gets to 10, press to calibrate manually. Or after 10s, gas automatically calibrates. After a successful interface, it displays 'Good 'and vice, display 'Fail '.● Relay Set: Relay output mode, type can be selected for always or pulse, just as what shows in Figure22: Always: when alarming occurs, relay will keep actuating. Pulse: when alarming occurs, relay will actuate and after the Pulse time, the relay will be disconnected. Set according to the connected equipment.

to calibrate manually. Or after 10s, gas automatically calibrates. After a successful interface, it displays 'Good 'and vice, display 'Fail '.● Relay Set: Relay output mode, type can be selected for always or pulse, just as what shows in Figure22: Always: when alarming occurs, relay will keep actuating. Pulse: when alarming occurs, relay will actuate and after the Pulse time, the relay will be disconnected. Set according to the connected equipment.

Figure 22: Switch mode selection

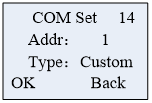

Note: The default setting is Always mode output 7.4.4 Communication settings: Set relevant parameters about RS485

Figure 23: Communication settings

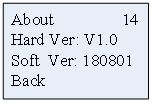

Addr: address of slave devices, range: 1-255 Type: read only, Custom (non-standard) and Modbus RTU, the agreement can not be set. If RS485 is not equipped, this setting will not work. 7.4.5 About Version information of display device is shown in Figure 24

Figure 24: Version Information

Warranty Description

The warranty period of the gas detection instrument produced by my company is 12 months and warranty period is valid from the date of delivery. Users shall comply with the instructions. Due to the improper use, or poor working conditions, the instrument damage caused is not in the scope of the warranty.Important Tips

1. Before using the instrument, please read the instructions carefully. 2. The use of the instrument must be in accordance with the rules set in the manual operation. 3. The instrument maintenance and replacement of parts should be processed by our company or around the pit. 4. If the user is not in accordance with the above instructions to boot repair or replacement parts, the reliability of the instrument shall be the responsibility of the operator. 5. The use of the instrument should also abide by the relevant domestic departments and factory equipment management laws and rules.